Servo Motor Sizing for Horizontal Ball Screw Applications: A Practical Guide

Introduction

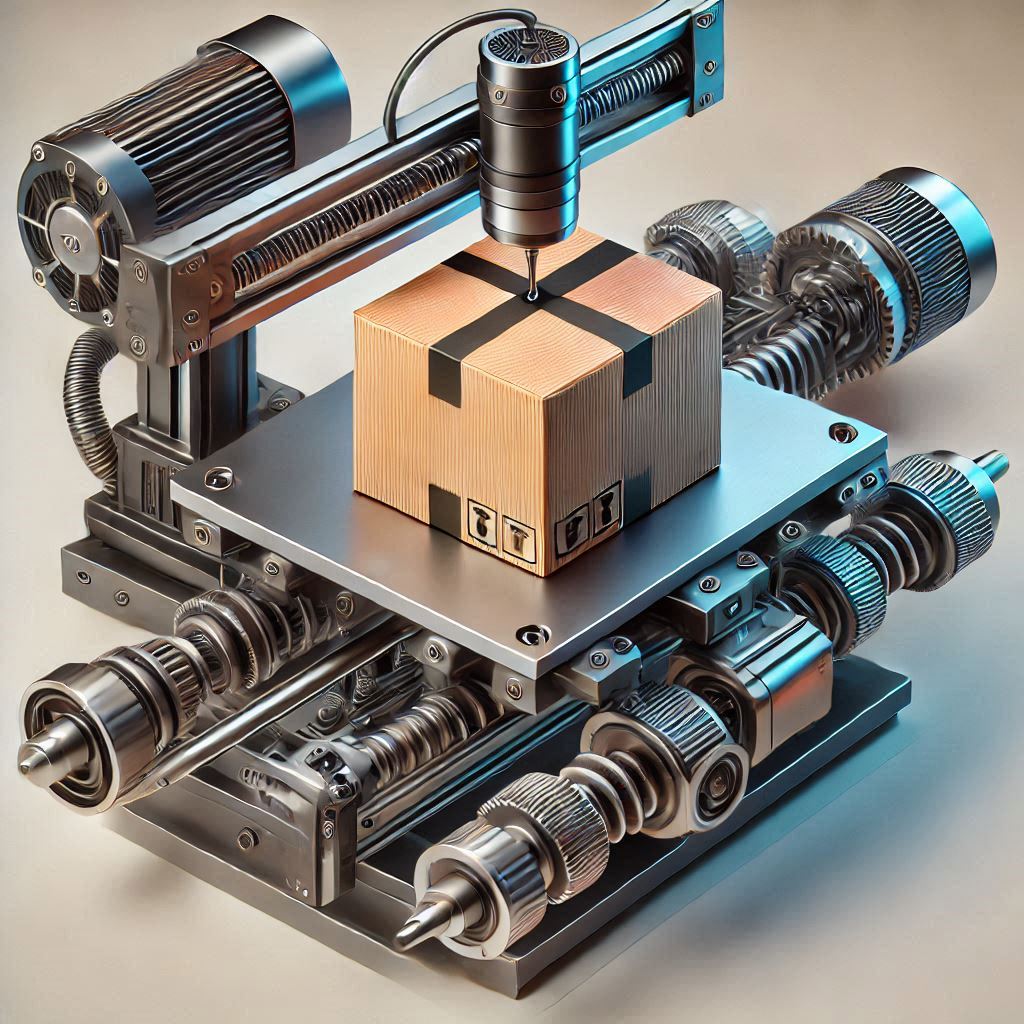

In precision automation, correctly sizing a servo motor for horizontal motion systems is crucial. This article presents a practical example of a ball screw-driven platform.

TIP

- Calculations in this article are live and can be used like an app

- All physical quantities in the calculations come with automated unit conversion.

Application Scenario

Consider a horizontal platform:

- Load mass (m):

- Ball screw lead (L):

- Maximum speed (v):

- Maximum acceleration (a):

- Ball screw efficiency (η):

- Linear guide friction coefficient (μ):

- Gravitational acceleration (g):

Calculation Process

1. Force Analysis

Acceleration force (Fa):

Preload friction:

- Normal force:

- Guide friction:

- Ball screw friction(assumed to be for typical preload friction)

- Normal force:

Total force (F):

2. Torque Calculations

- Required Torque (T1):

- RMS Torque (assuming 50% acceleration & deceleration time):

For a typical point-to-point motion:

- Acceleration phase: Peak required torque T1

- Constant velocity: Lower torque due to friction only

- Linear guide friction at Ff1

- Ball screw friction at Ff2

- Total friction force:

- Resultant Torque

- Deceleration: Negative peak required torque -T1

Assuming a cycle below:

- Acceleration:

- Constant velocity:

- Deceleration:

- Total cycle time:

Trms = √[(Tacc² × t1 + Tconst² × t2 + Tdec² × t3)/tc]

(calculated with duty cycle)3. Motor Requirements

Assuming safety margin .

Peak Torque T Required:

Peak Torque Trms Required:

Motor Speed and Power Required:

Key Insights

- RMS torque is critical for thermal considerations

- Friction forces in horizontal systems are much lower than vertical ones

- System efficiency significantly impacts required motor torque

- Safety margins ensure reliable operation and tuning headroom

Conclusion

Proper servo sizing requires understanding both peak and RMS torque requirements. This methodology ensures optimal motor selection while avoiding oversizing, leading to cost-effective and efficient solutions.Consider higher specifications if system has frequent start-stop operations.