| 术语定义 Definition of terms | ||

| 1.1 | 步距角-步进电机固有的机械角度, 一般为1.8°, 0.9°, 0.72° 等。 | Step angle-mechanical angle inherent in stepping motor, generally1.8°, 0.9°, 0.72°. |

| 1.2 | 驱动电压-开始工作所需的驱动器供电电压。 | Drive voltage-the drive supply voltage required to start operation. |

| 1.3 | 丝杆类型-根据摩擦特性可以分为3种,即滑动丝杆,滚动丝杆和静压丝杆。 | Screw type-according to the friction characteristics can be divided into 3 types, namely sliding screw, rolling screw and static screw. |

| 1.4 | 导程-指电动机每转动1圈时,工作台向直线方向前进的距离。 | Lead-the distance the table moves in a straight line for each turn of the motor. |

| 1.5 | 行程-工作台可前进的总距离。 | Stroke-total distance the table can travel. |

| 1.6 | 精度等级-根据使用要求分为 CO,C3,C5,C7,C10 五个等级。 | Accuracy grade-four grades of C3, C5, C7 and C10 according to the requirements of use. |

| 1.7 | 输出推力-在固定转速下工作台持续输出的最小推力。 | Output thrust-the minimum sustained thrust output of a table at a fixed speed. |

| 选型&计算 Selection and Calculation | ||

| 2.1 | 丝杆的传动效率。 | Transmission efficiency of screw rod. |

| 2.1.1 | T型丝杆的传动效率 为 3.14。 | The transmission efficiency of t-screw is 3.14. |

| 2.1.2 | 滚珠丝杆的传动效率 为 5.338。 | The transmission efficiency of ball screw is 5.338. |

| 2.2 | 丝杆寿命-丝杆寿命通常以回转数,回转时间,行走距离数(Km)来表示。 | Screw life-the screw life is usually expressed by the number of rotations, rotations, travel distance (Km) . |

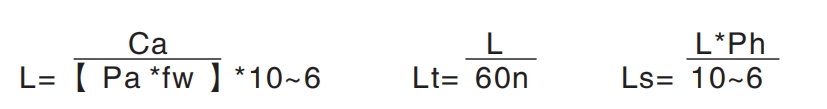

|

||

|

L:额定疲劳寿命(rew) Lt:寿命时间(h) Ls:行走距离寿命(Km) Ph:导程 FW:负载系数(运转条件系数) Pa:轴向负载(kgf) Ca:额定负载 n:回转数 |

L: Rated Fatigue Life (rew) Lt: Life Time (h) Ls: Service Life Distance (Km) Ph: Lead FW: Load Factor (Operating Condition Coefficient) Pa: Axial Load (kgf) Ca: Rated Load n: Rotation Speed |

|

| 2.3 | 电动缸额定推力计算 | Calculation of rated thrust of electric cylinder. |

| 2.3.1 | 额定推力=电机扭力*丝杆传动系数/丝杆导程*减速比 | Rated thrust = motor torque * Screw Drive Factor/screw lead * deceleration ratio. |

| 2.3.2 | 额定速度(mm/s)=电机额定转速/60*丝杆导程*减速比 | Rated speed (mm/s) = Motor rated speed/60 * lead * reduction ratio. |

| 2.3.3 | 电动缸的实际推力≈应按照计算出的推力*60%-85%的安全系数 | The actual thrust ≈ of the electric cylinder should be 60% to 85% of the calculated thrust Factor of safety |

ref: http://www.dgm-c.com/T-Support.html

Disclaimer: the content listed above are just for showcasing the usage of the

physical-quantity web compoent,

and the embedded calculations with automated unit conversion.